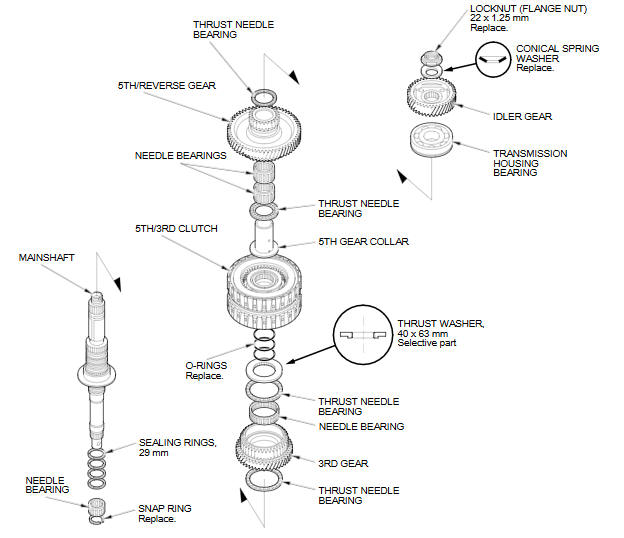

Honda Fit: Mainshaft Disassembly, Inspection, and Reassembly (A/T)

-

Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

-

Inspect the splines for excessive wear and damage.

-

Check the shaft bearing surfaces for scoring and excessive wear.

-

Before installing the O-rings, wrap the shaft splines with tape to prevent O-ring damage.

-

Lubricate all parts with ATF during assembly.

-

Install the conical spring washer and the 40 x 63 mm thrust washer in the direction shown.

-

Replace the locknut and the conical spring washer with new ones when assembling the transmission.

-

Check the axial clearance of 3rd gear.

See also:

Maintenance

...

Driver's Airbag Replacement

NOTE:

If replacing the driver's airbag after deployment, refer to

Component Replacement/Inspection After Deployment for a

complete list of other parts that must also be replaced.

...

Front Stabilizer Bar Replacement

Removal

Remove the front subframe.

Remove the steering gearbox from the front subframe.

Remove the flange bolts (A) and the bushing holders (B), then remove the

...