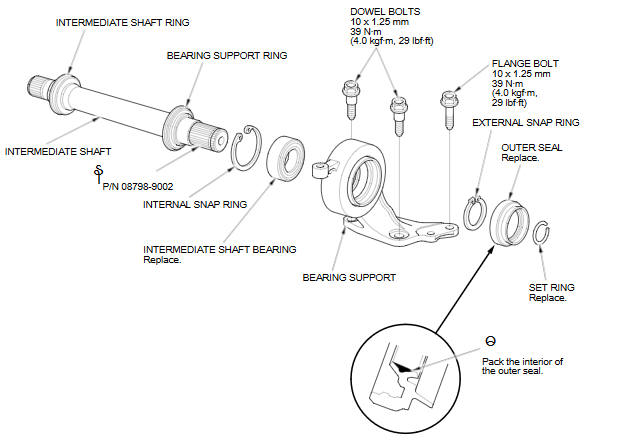

Honda Fit: Intermediate Shaft Reassembly (A/T)

Exploded View

Special Tools Required

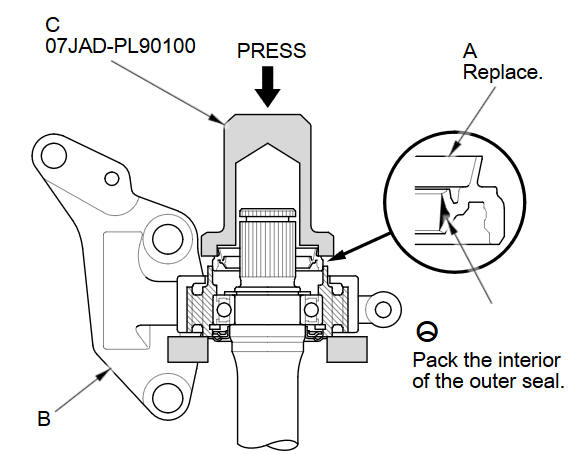

- Oil Seal Driver, 65 mm 07JAD-PL90100

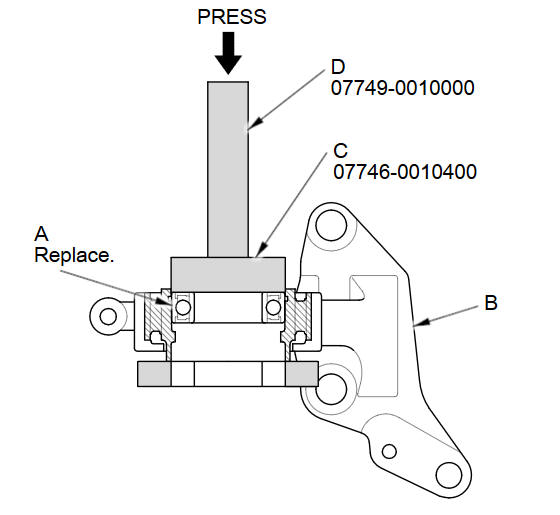

- Bearing Driver Attachment, 52 x 55 mm 07746-0010400

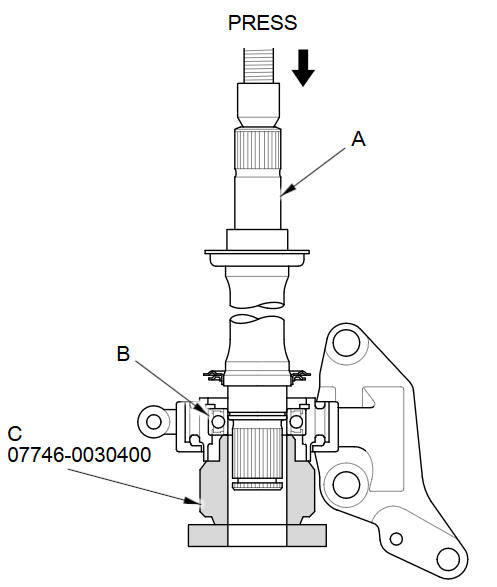

- Bearing Driver Attachment, 35 mm I.D. 07746-0030400

- Driver Handle, 15 x 135L 07749-0010000

NOTE: Refer to the Exploded View, as needed, during this procedure.

-

Clean the disassembled parts with solvent, and dry them with compressed air.

NOTE: Do not wash the rubber parts with solvent.

-

Press a new intermediate shaft bearing (A) into the bearing support (B) using the 52 x 55 mm bearing driver attachment (C), the 15 x 135L driver handle (D), and a press.

-

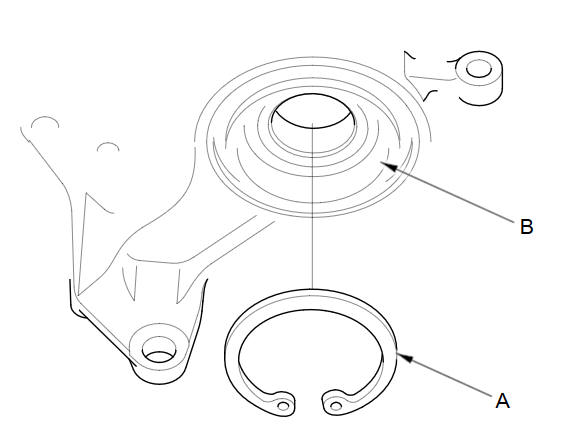

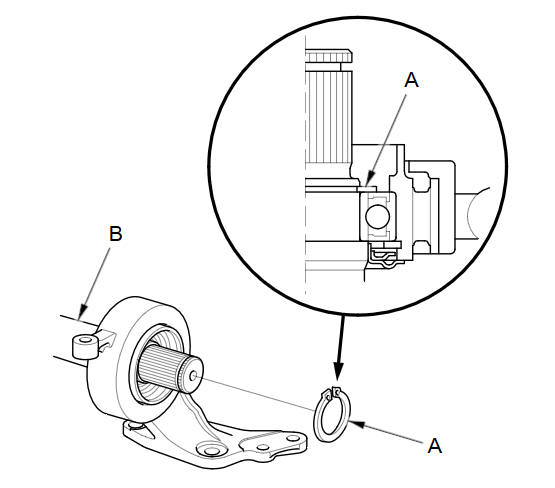

Install the internal snap ring (A) into the groove (B) of the bearing support.

-

Press the intermediate shaft (A) into the shaft bearing (B) using the 35 mm inner bearing driver attachment (C) and a press.

-

Install the external snap ring (A) in the groove of the intermediate shaft (B).

-

Install a new outer seal (A) into the bearing support (B) using the 65 mm oil seal driver (C) and a press. Press the seal until it is 0В±0.2 mm (0В±0.008 in) below the surface of the bearing support end.

See also:

Fuses

The vehicle’s fuses are contained in three fuse boxes.

The interior fuse box is behind the driver’s coin tray. To access it, remove

the tray by turning the dial counterclockwise then pulling ...

HandsFreeLink System Description

HandsFreeLink Control Unit Connector for Inputs and Outputs

...

Setting Up Speed Dialing

PHONE button

► Speed Dial 1 or Speed Dial 2

Create speed dial entries with voice tags for easy calling.

1. Select Add New.

2. Select a number entry option.

3. Select a number.>

4. ...